Wet Wipes Quality Assurance by Rebel Converting

Quality is vital to the success of our business, our sustainability, and our customer satisfaction.

With our expertise, the possibilities for your brand are limitless. We don’t just meet industry standards—we exceed them, ensuring every product reflects our commitment to excellence, innovation, and reliability. Whether you’re launching a new line or scaling an existing one, Rebel’s deep industry knowledge, agile production, and advanced customization capabilities make us the partner that grows with your brand.

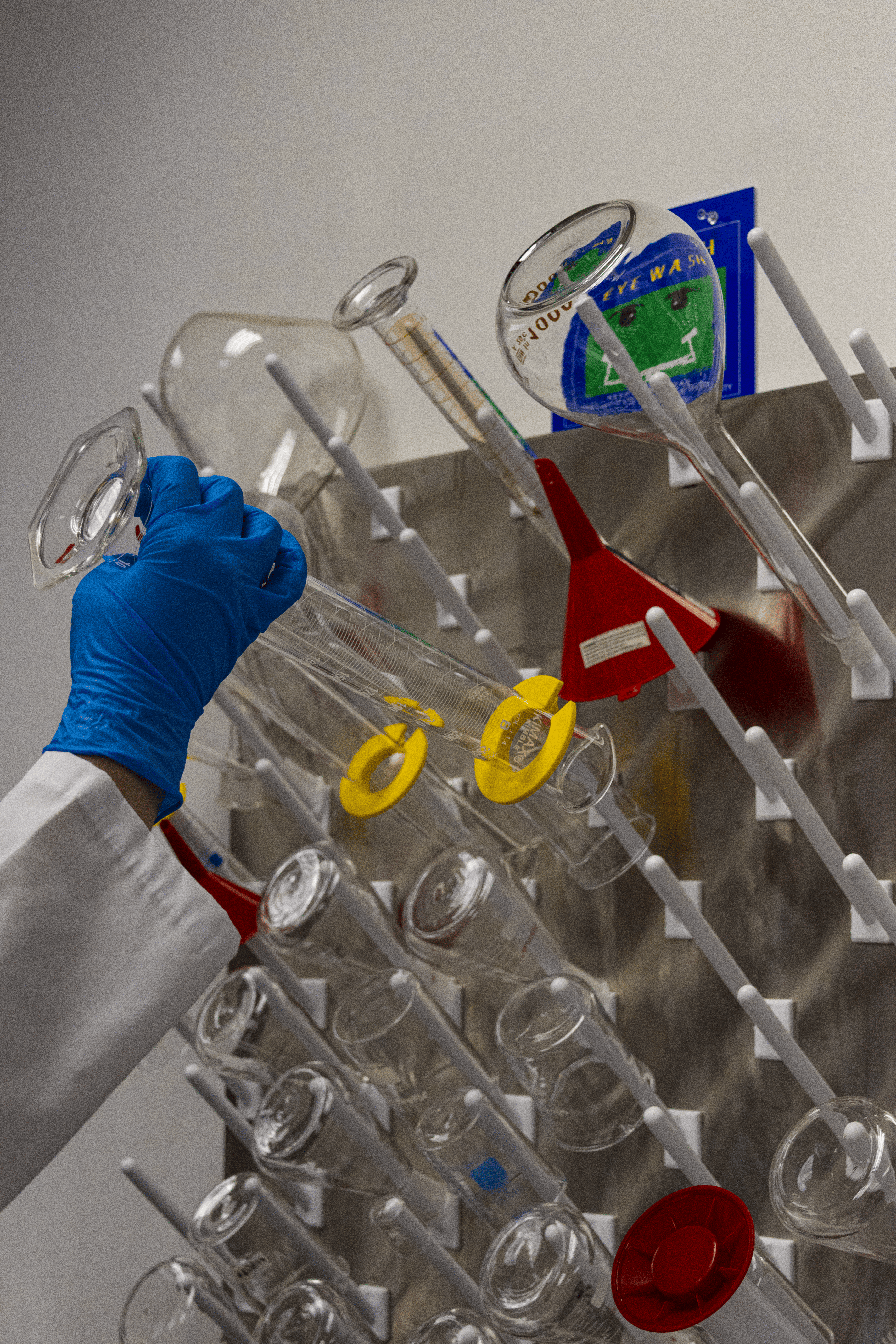

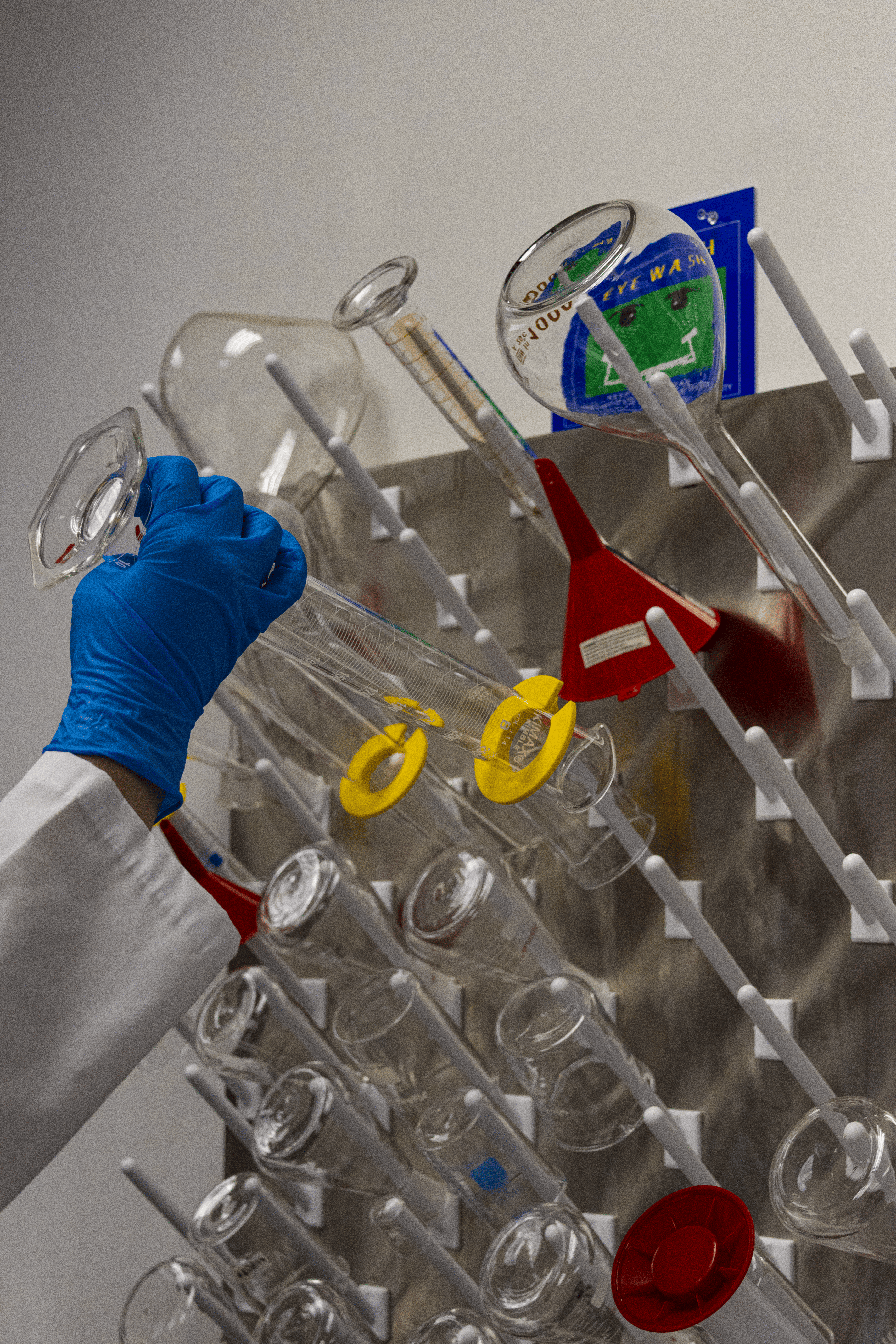

Our quality activities include raw material testing, validation protocol development and execution (IQ, OQ, PQ), process control / routine inspections, controlled documentations, analytical testing, final product review and release, development, RM Testing, quality control, production control, distribution, inspection, product stability, validation, controlled documentation, final product review and training.

Our Quality Department is integral to Rebel’s success, ensuring that products are consistently produced to meet high standards. Through rigorous inspection, process management, and a focus on continuous improvement, the quality team helps prevent defects, reduces waste, and ensures that the company delivers safe and reliable products to customers.

Rigorous Quality Control for Wet Wipes

REBEL CONVERTING’S Key Functions

Quality Control

- Inspection and Testing

- Product Sampling

- Non-conformance Management

Quality ASSURANCE

- Process Improvement

- Training and Development

- Audits and Compliance

DOCUMENT CONTROL

- Record Keeping

- Standards and Procedures

SUPPLIER QUALITY MANAGEMENT

- Supplier Evaluation

- Incoming Material Inspection

ROOT CAUSE ANALYSIS AND CORRECTIVE ACTIONS

- Problem Solving

- Corrective and Preventive Actions

REGULATORY COMPLIANCE

- Adhering to Standards

- Documentation for Compliance

CONTINUOUS IMPROVEMENT

- Reduce Waste, Improve Efficiency, and enhance the overall quality of products

- Customer Satisfaction

Customer-Focused Quality Policy and Partnerships

QUALITY AT THE SOURCE

Our ASC Quality Department brings a wide range of industry knowledge, which we leverage across our entire manufacturing operation incorporating:

- In-depth understanding of FDA and EPA requirements

- R&D for individual customers

- Process and procedure audits

- Quantitative lab testing

- Our lab supports many different market segments including hospital hygienic wipes, degreaser towelettes and surface disinfectants, (EPA).

- We use validated testing equipment to analyze anything from a simple pH test to sodium hypochlorite concentration.

QUALITY POLICY

- Quickly and efficiently meeting customer requirements

- Maintaining a safe, healthy, and injury free environment to all employees

- Providing support and service that exceeds customer expectations

- Effectively creating, implementing, and monitoring quality standards

- Continually improving the effectiveness of our quality system

- Developing and maintaining mutually beneficial partnerships with our customers, suppliers and our community

- Our management team, by direction and example, will ensure that this policy is understood and implemented throughout our organization

Ready to work with us?

Reach out today and see the REBEL CONVERTING difference.