Table of contents

- Expanding Coreless Roll Packaging with Digital IML for One-Gallon Buckets

- Coreless Roll Wet and Dry Wipe Manufacturing at Scale

- Digital In-Mold Labeling (IML) for Large-Format Contract Wet Wipes Packaging

- X-treme Canister Designed for Coreless Roll Performance

- Contract Wet Wipes Packaging Formats for a Range of Wipe Applications

- Supporting Flexible Wipe Program Development

- Packaging Considerations in Professional Wipe Applications

- Learn More About Coreless Roll Wipe Manufacturing

Key Takeaways

- Rebel Converting specializes in contract wet wipes packaging, offering coreless roll formats for wet and dry wipes.

- The company has introduced digital in-mold labeling (IML) for one-gallon buckets, enabling high-quality graphics and low order quantities.

- Coreless roll wipes eliminate cardboard cores, reduce waste, and improve dispensing performance, making them ideal for professional use.

- Rebel’s X-treme canister enhances durability and integrates labeling for long-lasting use in demanding environments.

- The flexible approach supports quick iteration and caters to various wipe program needs, including private label and product development.

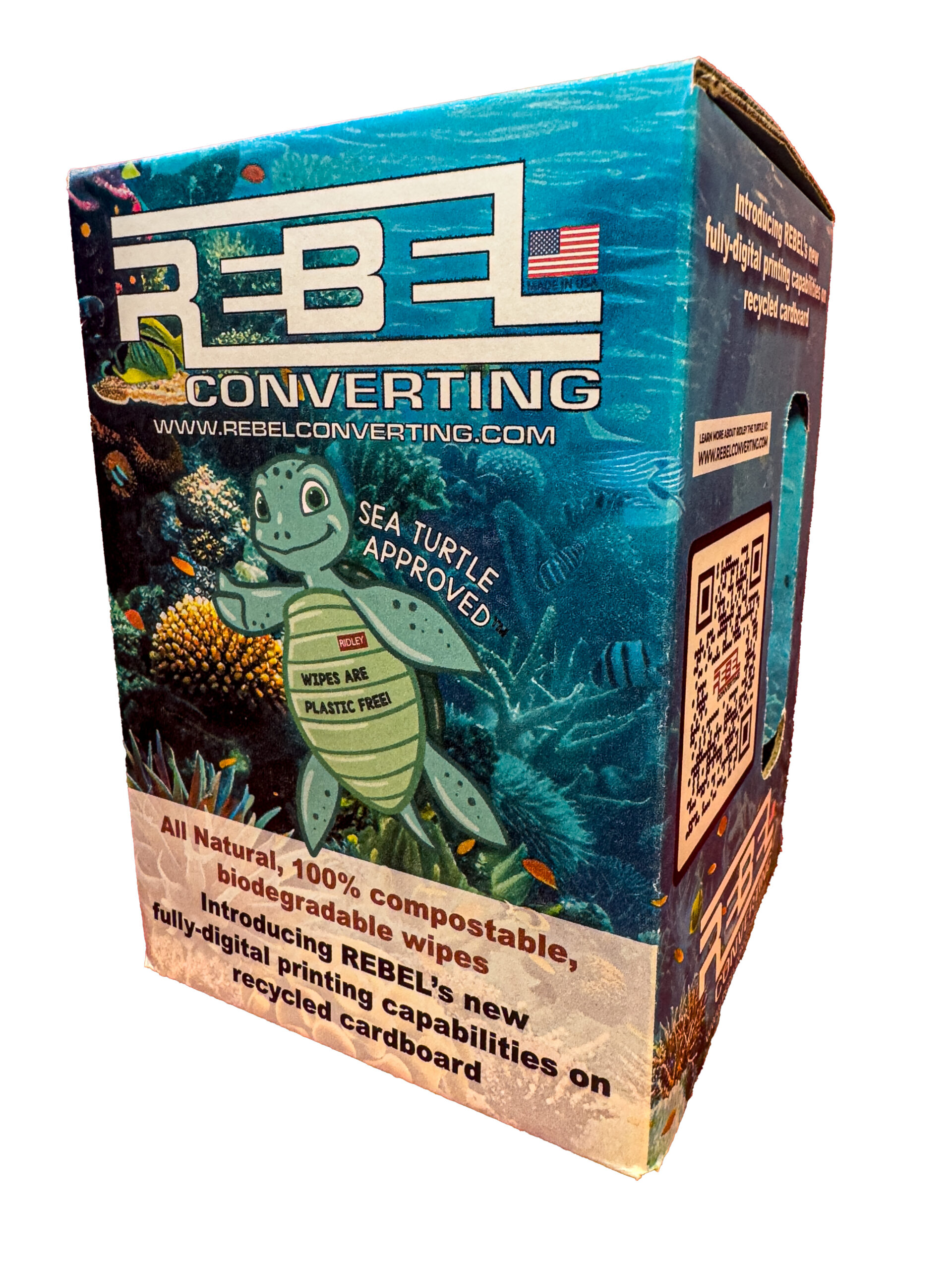

Expanding Coreless Roll Packaging with Digital IML for One-Gallon Buckets

At Rebel Converting, a U.S.-based contract manufacturer specializing in contract wet wipes packaging coreless roll wet and dry wipes, Rebel Convertings innovation extends beyond substrates and converting—it also includes packaging. To better support customers launching new products or expanding existing wipe programs, Rebel Converting has added full digital in-mold labeling (IML) for its X-treme canister, now available in one-gallon bucket formats.

This expanded capability allows customers to achieve high-resolution, magazine-quality graphics on durable, large-format wipe containers while maintaining low minimum order quantities (MOQs) and fast turnaround times.

Coreless Roll Wet and Dry Wipe Manufacturing at Scale

Rebel Converting specializes exclusively in coreless roll formats for both wet and dry wipes. With the capacity to convert over 2 billion square yards of material, Rebel Converting supports a wide range of industrial, commercial, medical, and institutional wipe applications.

Coreless roll wipes offer several functional and efficiency advantages, including:

- Elimination of cardboard cores

- Reduced material waste

- Increased usable wipe count per container

- Consistent dispensing performance

- Improved material utilization

These characteristics make coreless rolls well-suited for professional environments where reliability, efficiency, and performance are critical.

Digital In-Mold Labeling (IML) for Large-Format Contract Wet Wipes Packaging

Traditional in-mold labeling often requires large production volumes due to tooling and setup requirements. Rebel Converting’s digital IML process helps reduce those barriers, allowing customers greater flexibility during product development.

Digital IML capabilities include:

- Full-color, high-resolution graphics

- Low MOQs compared to conventional IML methods

- Faster design changes without plates or tooling

- Labels molded directly into the container for long-term durability

Because the label becomes part of the container wall during molding, IML packaging provides resistance to moisture, scuffing, and chemicals—an important consideration for industrial and commercial wipe applications.

X-treme Canister Designed for Coreless Roll Performance

The X-treme canister from Rebel Converting was developed to support coreless roll wipes used in demanding environments. The container design emphasizes durability, ease of dispensing, and compatibility with a range of wet and dry wipe materials for contract wet wipes packaging.

With the addition of digital IML and one-gallon bucket formats, the X-treme® canister provides:

- Reliable dispensing for coreless roll wipes

- Durable packaging for professional use

- Integrated labeling with long service life

- Flexibility across production volumes

This combination allows customers to balance performance requirements with branding and packaging needs.

Contract Wet Wipes Packaging Formats for a Range of Wipe Applications

Across both consumer and professional markets, packaging plays an increasingly important role in product performance, usability, and differentiation. In addition to large-format canisters and one-gallon buckets, Rebel Converting supports a broad range of packaging formats to meet varying application requirements.

Wet Wipes Packaging formats supported by Rebel Converting include:

- Retail packaging for consumer and commercial wipe programs

- Medical and healthcare packaging designed for controlled environments

- Large, high-count coreless rolls packaged in buckets and pouches

- Dry wipe rolls dispensed from Rebel Converting’s full digital printed corrugated dispensers

These options allow customers to align wipe format, dispensing method, and packaging design with specific end-use needs while maintaining consistency in coreless roll performance.

Supporting Flexible Wipe Program Development

As a family-run contract wipes manufacturer, Rebel Converting works closely with customers throughout the wipe program development process. The addition of digital IML and expanded contract wet wipes packaging options supports this collaborative approach by enabling faster iteration and reduced upfront commitment.

This flexibility can support:

- New wet wipe and dry wipe product development

- Private label and branded programs

- Pilot or regional product introductions

- Packaging updates or line extensions

Rebel Converting supports customers from material selection and roll configuration through packaging and full-scale production.

Packaging Considerations in Professional Wipe Applications

Across both consumer and professional markets, packaging must balance durability, usability, and presentation alongside product performance. Consistent branding, appropriate dispensing formats, and packaging designed for the intended environment are all key considerations.

By combining coreless roll manufacturing expertise, large-scale converting capacity, and flexible packaging solutions, Rebel Converting offers customers a practical approach to wet and dry wipe packaging that supports both operational and branding objectives.

Frequently Asked Questions

What are coreless roll wipes?

Coreless roll wipes are manufactured without a cardboard core, allowing for increased usable wipe count, reduced waste, and consistent dispensing performance.

What is digital in-mold labeling (IML)?

Digital in-mold labeling integrates high-resolution graphics directly into the container during molding, creating durable labels without separate adhesives or sleeves.

What packaging formats does Rebel Converting support for coreless rolls?

Rebel Converting supports coreless roll wipes in canisters, retail and medical packaging, large-format buckets and pouches, and dry wipe rolls dispensed from digitally printed corrugated dispensers.

Can digital IML be used for low production volumes?

Digital IML allows for lower minimum order quantities compared to traditional IML methods, making it suitable for new product development and packaging updates.

Learn More About Coreless Roll Wipe Manufacturing

To learn more about Rebel Converting’s coreless roll wet and dry wipe manufacturing capabilities, digital IML packaging options, or wipe program development support, contact Rebel Converting to start a conversation.

0 Comments